Behind-the-Scenes at GOAT Sports: How We Bring Custom Merch to Life

Ever wonder what happens after you hit "submit" on that custom team store order? Or how your team's logo transforms from a digital file into that perfect hoodie your star player can't stop wearing?

Welcome to the wild, creative, and surprisingly intricate world of custom sports merchandise production at GOAT Sports. We're pulling back the curtain to show you exactly how we turn your vision into reality: from that first design conversation to the moment your gear lands in your hands.

It All Starts With Your Story

Before any ink hits fabric or any design software gets fired up, we sit down and listen. Really listen.

"Every single project begins with understanding the heart of the team," says Sarah Chen, our Lead Design Specialist. "Is this a scrappy high school team looking to make their mark? A youth league wanting to build community pride? Or maybe a semi-pro organization ready to level up their brand presence?"

The conversation matters because context drives everything. A championship-bound college team needs different energy than a recreational adult league. A fundraising campaign for new equipment calls for different messaging than celebrating a retiring coach.

We've learned that the best custom merchandise tells a story. Your story.

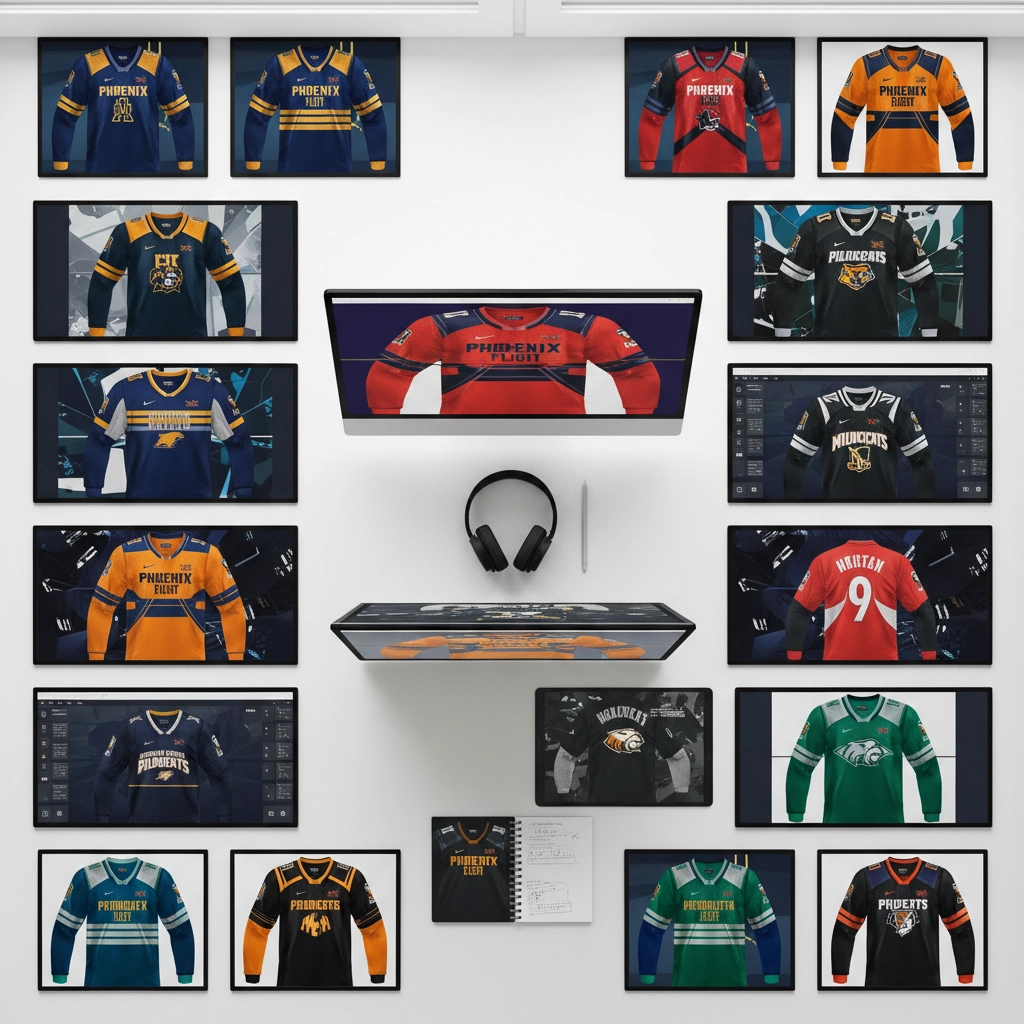

The Design Process: Where Magic Meets Strategy

Once we understand your vision, our design team gets to work. But this isn't just about making things look cool (though we definitely do that too).

Step 1: Concept Development Our designers start by researching your sport, your region, and your competition. What works in your league? What doesn't? What would make your fans do a double-take in the stands?

"I spend hours studying successful sports brands at every level," explains Marcus Rodriguez, Senior Graphic Designer. "The goal isn't to copy: it's to understand what resonates and then create something uniquely yours."

Step 2: Digital Mockups This is where your ideas start taking shape. We create detailed mockups showing how your design will look on different products: from jerseys to hoodies to those surprisingly popular dad hats.

Step 3: Feedback and Refinement Here's where we separate ourselves from the competition. We don't just send you a design and call it done. We collaborate. We iterate. We make sure every detail is exactly right before moving to production.

Production: Where Precision Meets Passion

The production floor at GOAT Sports is where the real magic happens. It's part high-tech laboratory, part artist's studio, and part manufacturing powerhouse.

Quality Control From Day One Before any production run begins, we test everything. Fabric quality, color matching, print durability: nothing gets mass-produced until it passes our standards.

"We've built relationships with suppliers who understand that a youth league jersey needs to survive grass stains and victory celebrations just as much as a professional team's gear needs to look perfect under stadium lights," says Production Manager Lisa Park.

The Art of Color Matching Getting colors right is harder than it looks. That perfect shade of blue your team has used for twenty years? We have color-matching technology that ensures your new merchandise matches exactly: not "close enough," but exactly.

Print Techniques That Actually Last Not all printing is created equal. We use different techniques depending on the design, the fabric, and how the item will be used:

- Screen printing for large quantities and bold, simple designs

- Digital printing for complex, detailed artwork and smaller runs

- Embroidery for that premium, professional look that lasts forever

- Heat transfer for special materials and quick turnarounds

Behind the Scenes: Real Stories from Real Projects

The Midnight Rush: State Championship Edition Last spring, the Riverside High Eagles made an unexpected run to the state championship. With 48 hours' notice, they needed 200 championship t-shirts for their fan section.

"We had our entire team working around the clock," remembers Production Supervisor Tony Blake. "Design approved by 11 PM, first prints running by 6 AM, finished shirts in coaches' hands by 5 PM the next day. Seeing those kids win while wearing our shirts? That's why we do this."

The Small Town Comeback When the Millfield Miners: a semi-pro baseball team: came to us, they hadn't updated their look in fifteen years. The town was losing interest, attendance was down, and players were talking about folding the team.

We worked with them to create a complete brand refresh: new logo, new colors, new merchandise strategy. Six months later? Sold-out home games and a waiting list for season tickets.

"Sometimes custom merchandise isn't just about looking good," explains Chen. "It's about giving a community something to rally around."

Technology Meets Tradition

Our production facility combines cutting-edge technology with time-tested craftsmanship. We've invested in digital printing equipment that can reproduce photographic detail, embroidery machines that create museum-quality work, and color-matching systems that would make NASA jealous.

But technology is just the tool. The real value comes from our team's experience and attention to detail.

Quality Control: The GOAT Standard

Every single item goes through our quality control process before it ships. No exceptions.

The Three-Check System:

- Design verification: Does it match the approved mockup exactly?

- Production quality: Are the prints crisp, colors accurate, and construction solid?

- Packaging check: Is everything organized, labeled, and ready for delivery?

"We've built our reputation on consistency," says Quality Control Manager Rachel Kumar. "Whether you're ordering 12 jerseys for your kid's team or 1,200 shirts for a fundraiser, every single item meets the same standard."

Sustainability: Doing Right by the Game

Sports teach us about teamwork, dedication, and responsibility. We take that responsibility seriously when it comes to our environmental impact.

We partner with suppliers who use eco-friendly inks, work to minimize waste in our production process, and offer organic and recycled fabric options for teams who want to make a statement beyond the scoreboard.

"Today's young athletes care about more than just winning games," notes Chen. "They want to know their gear aligns with their values. We're proud to offer options that perform great and do good."

The Moment of Truth: Delivery Day

All the design work, production precision, and quality control lead to one moment: when your custom merchandise arrives.

We've perfected our packaging and delivery process to ensure your gear shows up exactly when you need it, in perfect condition, and organized exactly how you requested.

"The best part of my job is the photos teams send us," says Customer Success Manager David Park. "Kids wearing our designs at championship games, parents proudly sporting team hoodies, coaches getting emotional because finally their program looks as professional as they've always dreamed."

Why the Process Matters

Great custom merchandise isn't just about looking good (though ours definitely does). It's about:

- Building team identity that players and fans can rally around

- Creating revenue streams through team stores and fundraising campaigns

- Establishing credibility that helps with recruiting, sponsorships, and community support

- Generating pride that extends far beyond the playing field

Whether you're a youth league coach trying to make your players feel special, a high school athletic director building school spirit, or a semi-pro organization ready to take your brand to the next level, the behind-the-scenes process matters.

At GOAT Sports, we've built our reputation on turning your vision into reality: with quality you can trust, service you can count on, and results that make everyone proud to be part of your team.

Ready to see what we can create for your organization? Let's start the conversation and bring your custom merchandise vision to life.